Centrifugal Pump Torque

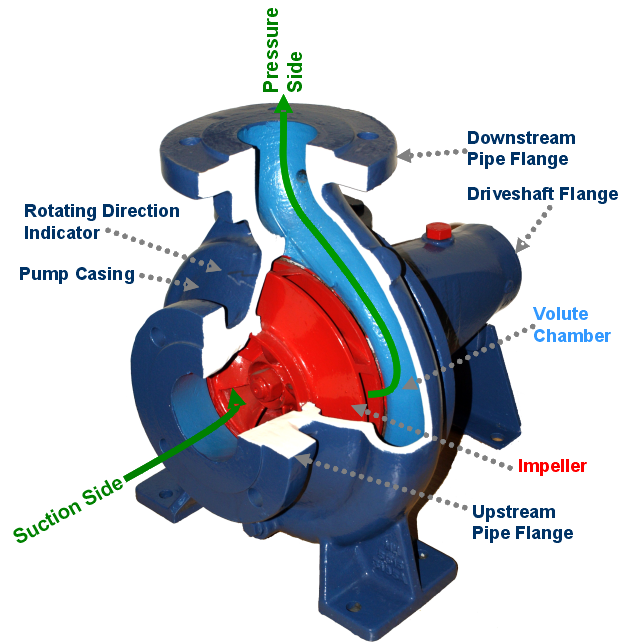

A centrifugal pump functions by casting fluid outward from the center of a spinning impeller. Fluid enters through the eye (center) of the impeller and, due to the spinning motion, is ejected outward into the volute chamber , the space outside the impeller and contained within the pump casing. The fluid thus gains kinetic energy from the impeller, much of which is converted to pressure energy upon slowing down on its way out of the pump. If the inlet and outlet piping are of the same diameter, the hydraulic power added to the system is , where is the volumetric flow rate and is the difference in pressure immediately before and after the pump. Fluid density is assumed constant at all locations within and outside of the pump.

Source: Fantagu - Own work, Public Domain, https://commons.wikimedia.org/w/index.php?curid=4332102

Source: Fantagu - Own work, Public Domain, https://commons.wikimedia.org/w/index.php?curid=4332102

Between the power applied to the pump's shaft to cause it to rotate and the power ultimately gained in the system fluid, some energy is lost. One major contributor to energy loss is recirculation of fluid within the volute, which is when some of the fluid fails to exit the pump and instead circles back around the volute. The overall efficiency of converting shaft power to hydraulic power depends on the amount of resistance in the system. For example, if flow is completely blocked , the pump efficiency is zero because no fluid is flowing regardless of any rotation of the impeller. In contrast, pump best efficiency points are typically in the range of efficiency.

Consider a traditional centrifugal pump, which always operates at a single rotational frequency , pumping water through a dirty strainer. Today, a worker cleans the strainer, which reduces the system resistance. Compared to before, the torque experienced by the impeller will _ _ _ _ .

This section requires Javascript.

You are seeing this because something didn't load right. We suggest you, (a) try

refreshing the page, (b) enabling javascript if it is disabled on your browser and,

finally, (c)

loading the

non-javascript version of this page

. We're sorry about the hassle.

At constant rotational frequency, the torque on the impeller depends on the rotational speed of the water it is pumping relative to that of the impeller. When the system resistance decreases , the flow rate increases . However, the rotational speed of the water touching the impeller is not the speed of the water moving through the pipes. Instead, we have to consider the speed of recirculation .

Consider, for example, the "shutoff" condition in which the pump is running but there is no flow. Precisely because the water is not moving through the system, it has time to accelerate around the pump volute and "keep up" with the spinning impeller. The same occurs with the water contained within the impeller. In contrast, if the water is flowing more quickly through the system, then as soon as the pump has accelerated some water out of the impeller and into the discharge piping, more water arrives at the eye, in need of acceleration.

More flow outside of the pump means less flow (recirculation) inside of the pump!

Please let me know if you have any feedback as this is my first posted problem!