Pulleys to the Rescue

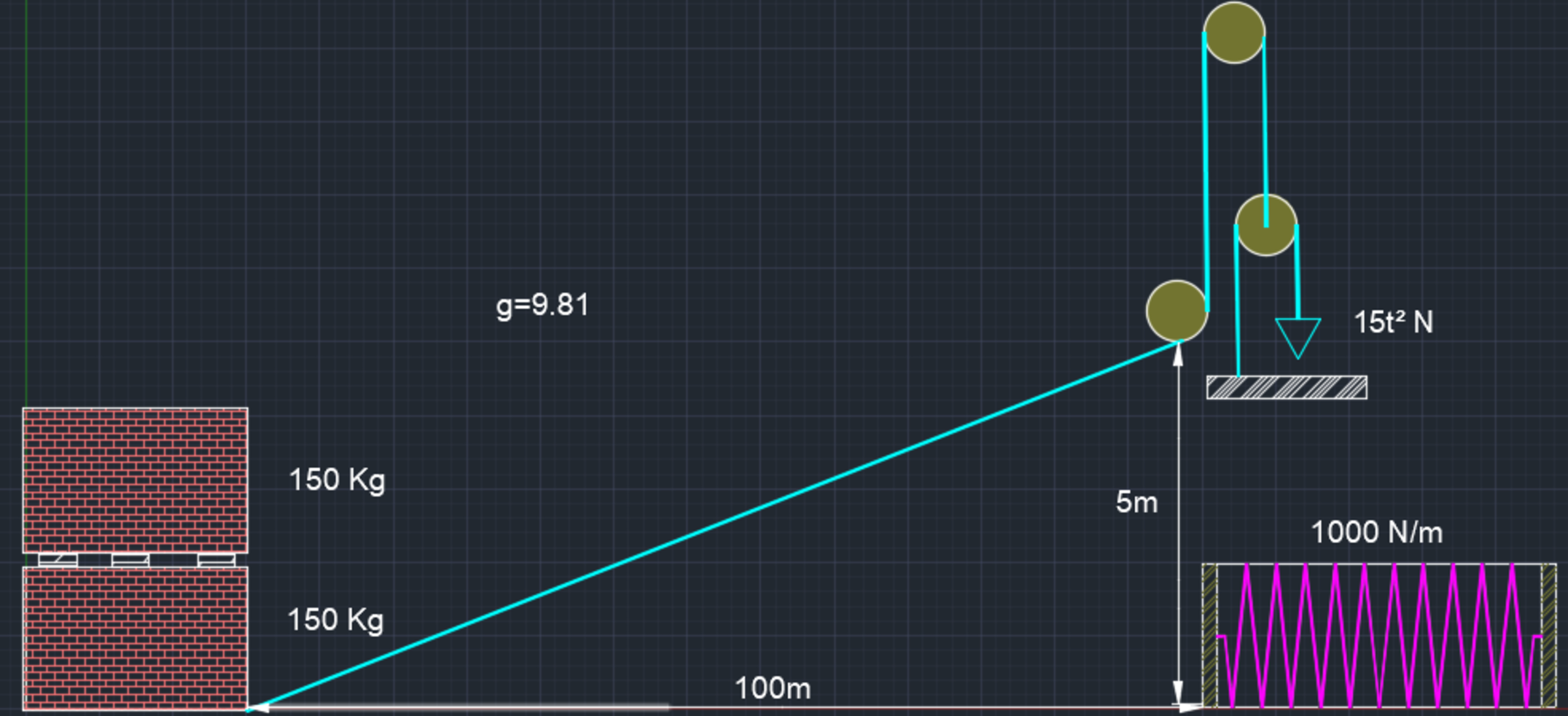

Workers at a brick manufacturing plant are behind schedule and need to move crates of bricks quicker. They decide to stack one crate upon another and modify the motor-cable system to accommodate the additional weight. The motor can exert a maximum force of 1500 N after 10 seconds. Before t=10 seconds the motor exerts a force F(t)=15t^2 N. The motor abruptly disconnects at t=12.5 sec. They aren't sure if the crates will remain stacked under the applied force but give it a try. There is a spring with k=1000 N/m at the motor. How far from the spring will the crates come to rest if the motor runs for a full 12.5 seconds? Note: The coefficient of static friction b/t the floor and crate = o.70. The coefficient of static friction b/t the crates = 0.65. The coefficient of kinetic friction = 0.45. There is no friction beneath the spring and energy is conserved. g=9.81 m/s^2.

Workers at a brick manufacturing plant are behind schedule and need to move crates of bricks quicker. They decide to stack one crate upon another and modify the motor-cable system to accommodate the additional weight. The motor can exert a maximum force of 1500 N after 10 seconds. Before t=10 seconds the motor exerts a force F(t)=15t^2 N. The motor abruptly disconnects at t=12.5 sec. They aren't sure if the crates will remain stacked under the applied force but give it a try. There is a spring with k=1000 N/m at the motor. How far from the spring will the crates come to rest if the motor runs for a full 12.5 seconds? Note: The coefficient of static friction b/t the floor and crate = o.70. The coefficient of static friction b/t the crates = 0.65. The coefficient of kinetic friction = 0.45. There is no friction beneath the spring and energy is conserved. g=9.81 m/s^2.

The answer is 1.964.

This section requires Javascript.

You are seeing this because something didn't load right. We suggest you, (a) try

refreshing the page, (b) enabling javascript if it is disabled on your browser and,

finally, (c)

loading the

non-javascript version of this page

. We're sorry about the hassle.